Completion Engineering

Effective completions based on the mechanical properties in your well

The NUSTIM family of services work in conjunction with one another to diagnose field-specific problems

The NUSTIM completion process is an eight-step design procedure, which links a normalized reservoir description (NULOOK) to past well records and history obtained in a field. Once this linkage is established, the process can then be used to predict well behavior prior to completion. Through implementation of the process, the optimal completion strategy for a new well or recompletion opportunity for an older well can be uncovered.

NUSTIM

NUSTIM is an engineered stimulation design system, which makes use of a detailed reservoir characterization. By utilizing the NULOOK petrophysical analysis, geomechanical properties are generated which determine the geometry of a particular completion scenario. By varying the stimulation design and applying economic factors to the completion and resulting production profile, a best design can be determined on an economic basis. This allows for the most value created to the customer based on their criteria.

NUSTIM Geomechanical Analysis

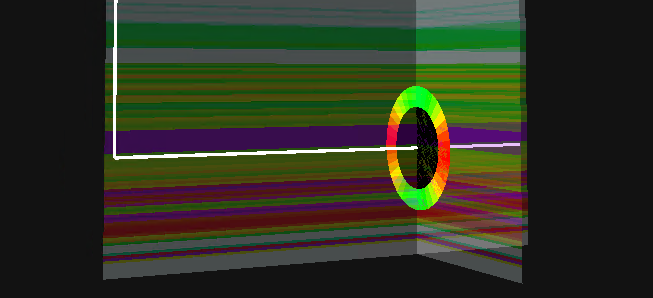

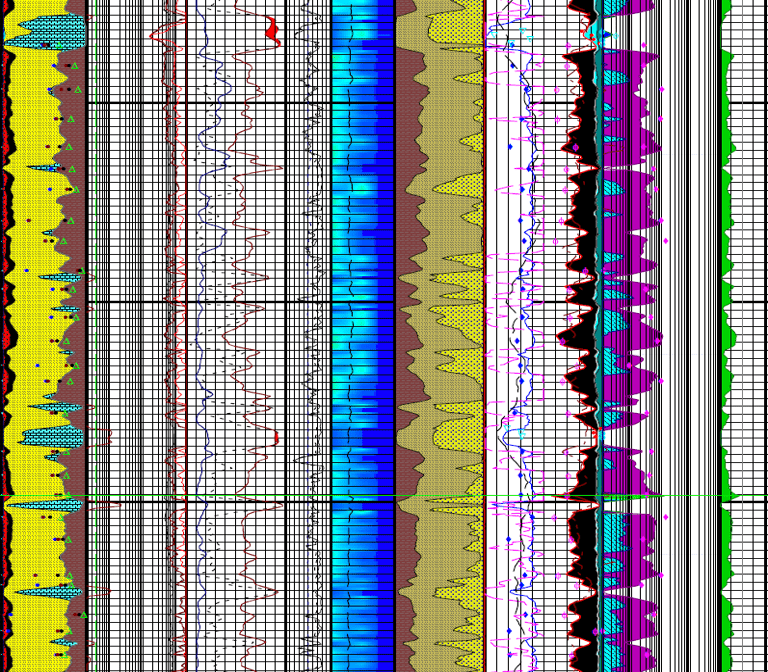

The NUSTIM Geomechanical Analysis consists of a modeled Poisson’s ratio, Young’s modulus, brittleness, pore pressure, in-situ stress profile, etc. This log summarizes step #2 in the NUSTIM process in which a geomechanical model is created and calibrated to existing well data for field wide application. This log is derived from the NULOOK reservoir description which incorporates all curve data allowing for a more complete solution than utilizing the measured sonic responses alone, and for proper environmental correction to be made. After the model is calibrated and with these curves now dependent solely on the proprietary textural NULOOK analysis, an accurate rock properties log can be generated and applied to all wells in the field, regardless of the presence of sonic measurements. NuTech’s geomechanical analysis is tied to your specific reservoir and gives you confidence in the predicted behavior of your reservoir.

NUSTIM Look Back

The Look Back service utilizes reservoir properties calculated from the NULOOK analysis combined with measured completion and test data for a well to determine if the reservoir is performing to its capabilities and to diagnose potential well problems. Look Back summarizes NuTech’s engineering analysis of past stimulation treatments, well tests, and production results while describing the calibration of the NUSTIM process. The service identifies reservoir parameters from the analysis of previous completions, matching those parameters to log responses.

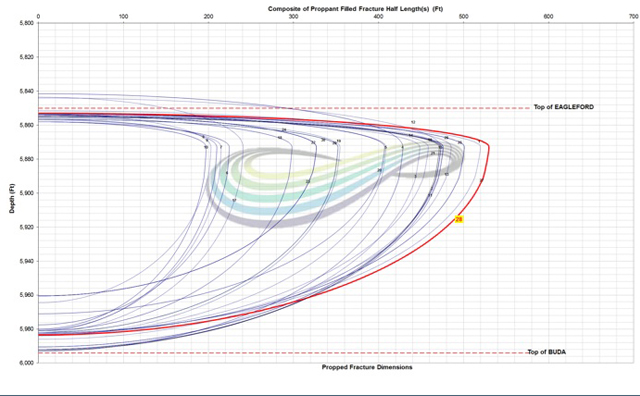

NUSTIM Fracture Injection Test Analysis

A Fracture Injection Test Analysis is a diagnostic fracture injection well test and analysis. When implemented properly this test will allow a breakdown of the formation and result in a direct measurement of formation stress, pore pressure, and permeability. These measurements are used to calibrate the NUSTIM process model and provide increased certainty in fracture dimensions and predicted production. The Fracture Injection Test Analysis results can be used as a decision point for a hydraulic fracturing treatment.

NUSTIM Look Forward

The Look Forward service provides an accurate production and reserve estimate for oil and gas wells based on the petrophysical parameters defined by NULOOK and a calibrated NUSTIM process model. This analysis incorporates a planned completion design providing a measure of economic viability.

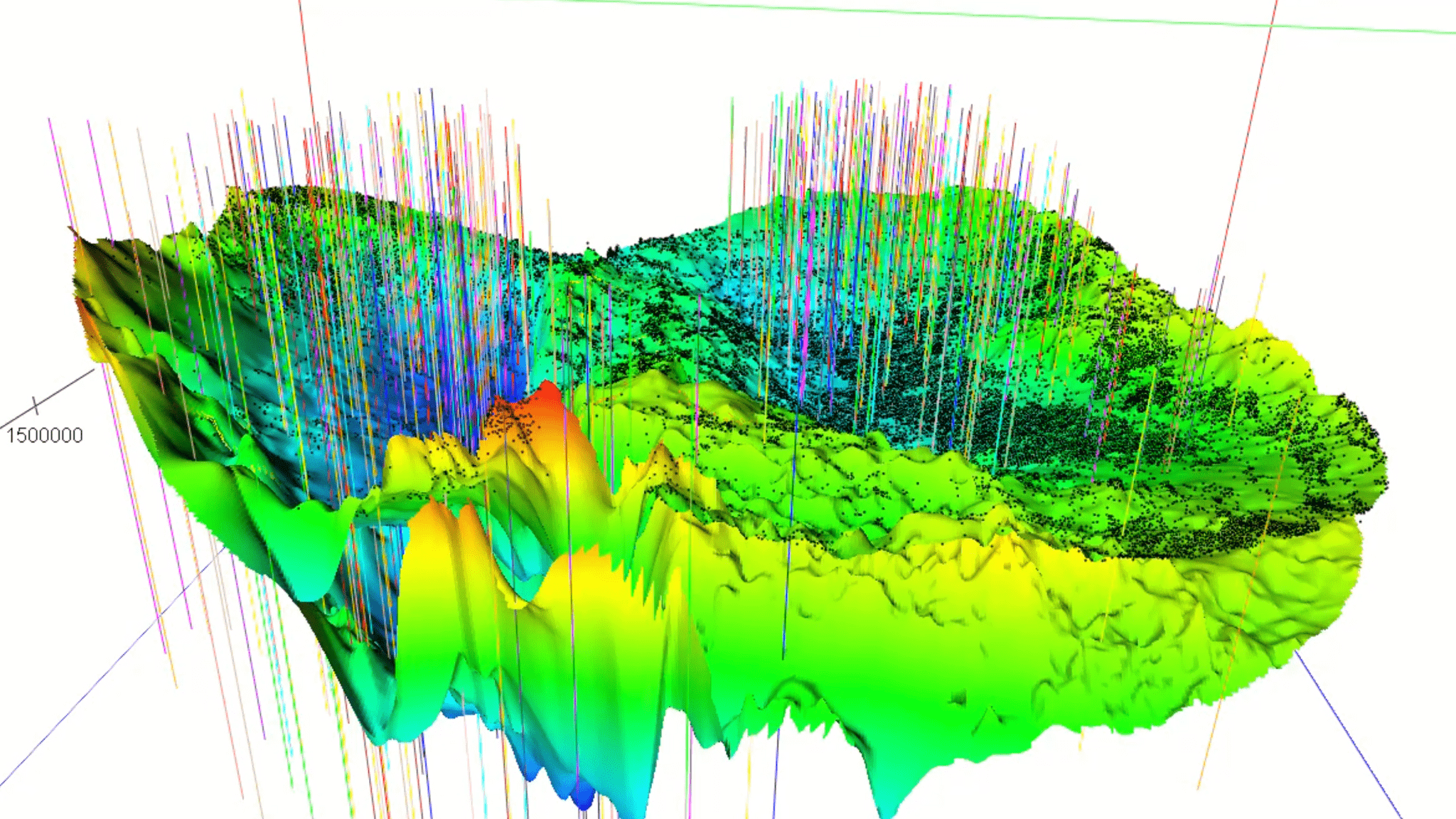

Integrated Solutions

Reservoir intelligence is gathered and interpreted by a team of experts unparalleled in the industry using innovative technology and a unique, integrated process.

Reservoir Engineering

Optimizing development of conventional and unconventional reservoirs.

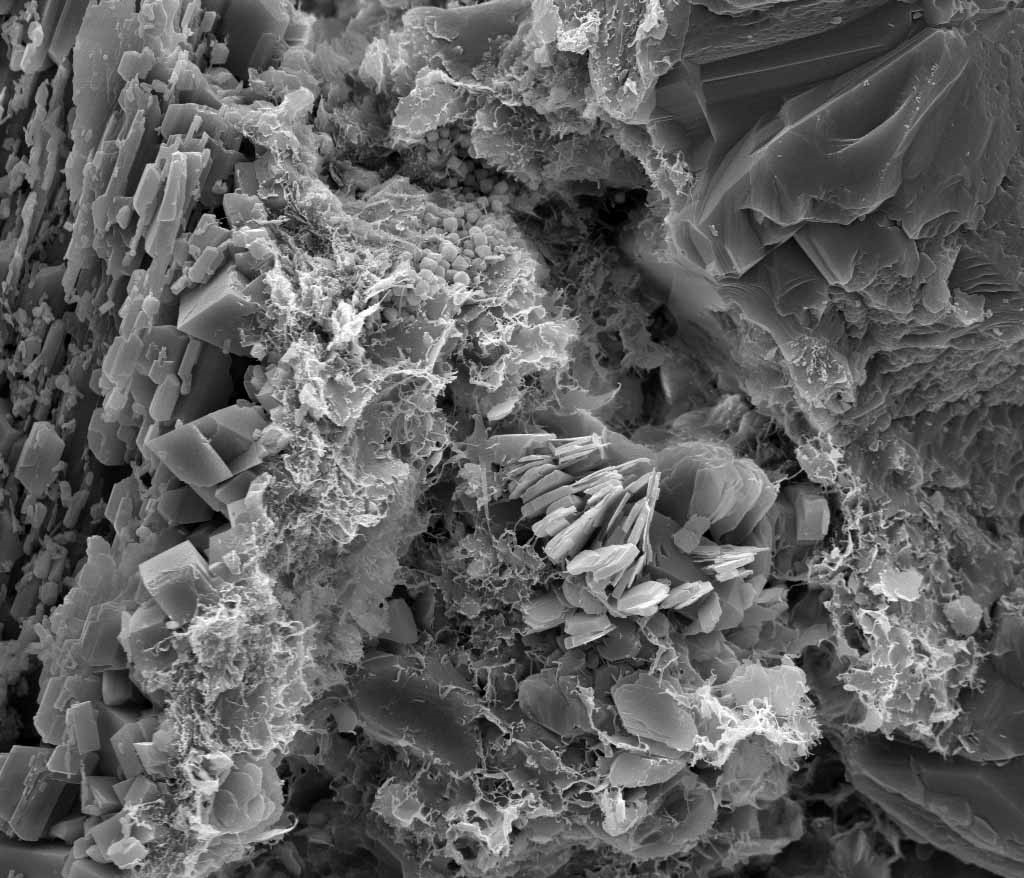

Core Analysis

Essential for determining oil and gas potential based off the experimental results of core samples.

NuTech Reservoir Experts:

- Discovered the full commercial potential of the Eagle Ford Shale.

- Confirmed a world class project that resulted in Argentina’s largest crude oil discovery in two decades.

quick stats

25,000

8,000

1,500

250

Completed 3D reservoir characterization studies.

30

Percent of wells processed have been unconventional.